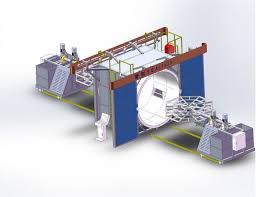

Rotational Molding the Rotomolding is the practice of plastics. The specialty with this method is it targets almost a infinite lifespan. It’s also known as rotational casting. There certainly are a variety of substances out there for precisely the same. However, probably the absolute most Custom Rotational Molding commonly molded cloth could be the grade of PE (Poly Ethylene ). These merchandise can be made from almost any form and dimensions with wonderful capacities from Tornado Shelters, trash cans, and toys into Air Cargo Containers. The software of these merchandise are never-ending.

The requirements of rotational Molding

Rotomolding requires a mold for producing any product or portion. To find the mold, an individual can decide to try several processes such as casting, manufacture, and machining.

The molds for Rotational Molding are made up of Aluminum, and also tools are retrieved out of Carbon Steel or Stainless Steel.

It’s implied this you should utilize seasoned people when it comes to rotomolding designs and processes to conserve the price.

It is important to tackle all the functions and features of the desirable product or component during the phase of designing it.

Great Things about rotomolding

The molds are taken for rotomoldingare built from Aluminum. The benefit of the same is that unlike Carbon steel, Aluminum performs greater from the cooling system cycles of Molding. The reason being the fact that exposing it makes it wear more powerful compared to carbon steel as steel begins massaging and transports that the rust into molded services and products also.

Several programs are likewise manufactured out of stainless steel.

Aluminum now is easier to keep up and alter compared to carbon steels.

These services and products are somewhat more lasting and have a very long battery life.

Several Men and Women are working to Generate roto-molded Products and working together with renowned business frontrunners because of such molding projects. However, with consultation, creating, then fabricating, an individual could possibly obtain their services and products made via this technique of molding very efficiently.